- Counting Machines

- REA Verifier

- X-Rite

- TMI

- Printing and Packaging

- Chemical Testing Analysis

- Tisch/AADCO

Mobile:13926416086

Fax:020-32032628

Products

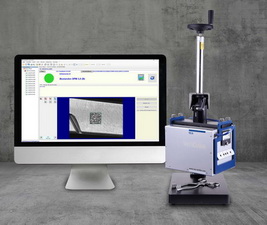

REA VeriCube DPM

with DOME Illumination

A high first read rate is of outstanding importance for

barcodes. Non-readable barcodes force manual entries

and increase the risk of errors. In addition to time delays,

this leads to disruptions in the operating process.

The REA VeriCube DPM (Direct Part Marking) verifies the

code quality of 2D codes. With the modern code verification

device, you will quickly find out how you can

improve the reading rates of the tested codes. With the

help of the detailed measurement results the code

quality can be optimized.

REA VeriCube DPM is designed for parts with high-glossy

surfaces and is used in all industries, both in the medical

product sector, such as surgical instruments, and in the

automotive and electronics sectors.

Whether lying, standing, or from top to bottom, virtually

any test sample can be measured contact-free in the

optimum measuring position.

The measuring system is based on a high-precision

optical module with a CMOS camera chip. During the

measuring process, ambient light influences are avoided.

The measurement of optical codes in compliance with

defined angles, distances and illumination allows

accurate and reproducible measurement results and

quality evaluations.

The measured values obtained are transferred to a PC

with the REA TransWin32 Evaluation Software for

evaluation and processing.

Features

n DOME Illumination

n Contact-free measurements by a CMOS camera

n Matte white tube insert in the measuring room for

extremely diffuse illumination

n Easy exchangeable camera modules to adapt to different

code sizes and measuring distances

n Different focus positions (0, +15mm, +45mm) above

the glass pane to measure parts where the code cannot

be placed on the pane with distance 0

n Selectable diffuse illumination (red or white light)

n Designed to operate in 3 positions to meet different

measuring requirements: sidewise, in upright position

and upside down. For complex 3D geometry parts the

REA VeriCube diffuse is mounted in a stand.

n Verification according to ISO/IEC 15415 for printed

matrix codes

n Verification according to ISO/IEC TR 29158 (formerly

AIM DPM guideline 2006) for direct part marking

matrix codes

n Verification in compliance with GS1 specifications

n Verification of GS1 data structures,

ISO/IEC 15459-x series of standards

and ISO/IEC 15418 / ANSI MH10.8.2

data structure analysis

n Verification of optional parameters for

optimizing the print process

n Multilingual user interface and reports

n For ease of use, settings can be stored in

customized profiles for fast selection

n Specific code selection to meet the

pharmaceutical industry demands

n Power supply via network cable

(Power over Ethernet)

n Easy removable and

exchangeable glass cover plate

n Network-compatible PC

evaluation software TransWin32

for Windows (multi user capable)

n Option Audit Trail for 21 CFR

part 11 and CGMP requirements

optionally available

Verification of surgical instruments Verification of surgical instruments

Code Types

Matrix Code Types (2D):

Data Matrix, DPM-Matrix Codes, QR-Code, Dotcode,

Micro QR-Code, Aztec Code, PDF 417, MicroPDF, HanXin

Code, Composite Codes, more under development

Barcodes (1D):

EAN-13, UPC-A, UPC-E ohne/mit Add-On, EAN-8,

2/5 Interleaved, ITF-14, Frachtpost, Code 39,

PZN-Code, Code 32, Code 128, GS1 Databar,

GS1 Databar Composite

Optional Codes:

2/5 3 Bars, 2/5 5 Bars, 2/5 IATA, 2/5 Baggage,

2/5 DHL Express (Frachtpost-Code), Code 39 Full ASCII,

Code 93, MSI, Plessey, Codabar Monarch (18),

LAETUS Pharmacode, LAETUS Mini Pharma Code

Options:

REA VeriCube stand, optional Symbologies, ScanLink,

Article Look up Software, Data Analysis

Data structures and properties:

n GS1 data structures (GS1 DataMatrix, GS1 QR-Code,

GS1-128, GS1 Databar, Composite)

n ISO/IEC 15418 / ANSI MH10.8.2 data structures

(AIAG, Odette, VDA, EDIFICE, HIBC, DOD, UPU…)

n EFPIA and PPN support for pharmaceutical industry

n Check digit control settings

n Size control settings

n Customizable date verification

n Measuring accuracy compliant to ISO/IEC 15426-2 and ISO/IEC 15426-1

n Red LED light 660 nm or white LED light, 4.000 °K

n Exchangeable camera module, resolution 2592 x 1944 pixel

n Camera focus and aperture pre-adjusted by factory

n Flip key panel to accomodate to preferred measuring position

n RJ45 Ethernet port for TCP/IP communication and PoE Power supply

n Key panel with on/off, Scan and customizable function keys

n Size: 200 x 150 x 150 mm (w/l/h), with key panel 210 mm width

n Weight: 2.600 g

n Windows 10 or later, 64bit support. The Audit Trail option requires

a 64-bit Windows version.

Specifications